What is a work permit?

A work permit in safety is a formal document that specifies the type, scope, location, and duration of high-risk or non-routine activities that require special precautions to prevent accidents or injuries. A work permit also identifies the potential hazards involved in the activity and the measures to be taken to control them. It ensures that the necessary precautions are taken before, during, and after work. A work permit is usually issued by a competent person who has assessed the risks and verified the safety conditions before, during, and after the work.

A work permit is signed by the person authorizing the work and the person performing it to ensure they understand and comply with the safety requirements. It is used to ensure that all necessary precautions are taken to minimize the risks associated with the work and to protect workers, the public, and the environment¹.

What is a Permit to Work System?

A permit-to-work system is a formal and documented procedure for controlling and managing hazardous or potentially hazardous work activities and ensuring they are carried out safely and efficiently. It is a way of communicating and controlling the risks associated with hazardous work, such as working at heights, confined spaces, hot work, electrical work, etc.

A Permit to Work System typically involves the following steps:

- The work requester identifies the scope, location, duration, and hazards of the work

- Assessing the risks and implementing the necessary control measures

- The work authorizer reviews the work request and approves or rejects it based on the risk assessment and the availability of resources. Obtaining authorization from a competent person to proceed with the work

- The work performer receives the permit to work and follows the instructions and precautions specified in it.

- Displaying the permit at the work site and informing all relevant parties

- The work supervisor monitors the work progress and ensures compliance with the permit to work conditions.

- The work verifier inspects the work site and confirms that the work has been completed satisfactorily and that the site has been restored to a safe state.

- Closing the permit when the work is completed or suspended and returned to the work authorizer.

A permit-to-work system helps prevent accidents, injuries, and damages by properly planning, coordinating, and supervising work. It also helps comply with the legal and regulatory requirements for health and safety in the workplace.

Why is a Permit to Work System Important?

A permit-to-work system is essential for several reasons:

- It identifies the hazards and risks associated with the work and specifies the control measures to prevent or minimize them.

- It defines the roles and responsibilities of the workers, supervisors, managers, and other parties involved.

- It establishes the communication and coordination channels between the workers and the authorities.

- It provides a record of the work done and the safety measures taken.

A permit-to-work system can help prevent accidents, injuries, and fatalities, protect the organization’s environment, property, and reputation, and improve the efficiency and quality of work by reducing errors, delays, and rework.

A permit-to-work system should be implemented according to the relevant standards, regulations, and best practices. It should also be reviewed and updated regularly to ensure effectiveness and suitability. A permit-to-work system should be supported by adequate training, supervision, and monitoring of the workers and their work activities.

The purpose of a permit to work (PTW) system

A PTW system ensures that work is carried out safely, efficiently, and according to established procedures and regulations. It is commonly used in construction, oil and gas, and chemical manufacturing, where work activities may pose significant risks to workers, the public, and the environment.

In a PTW system, a permit is issued by a designated authority, such as a supervisor or safety manager, to authorize specific work activities. The permit outlines the nature of the work, the potential hazards involved, and the measures that will be taken to control these hazards. The permit may also specify the qualifications and training required of the workers carrying out the work and any additional safety equipment or procedures that must be followed.

What are the Benefits of a Permit to Work System?

The benefits of a permit-to-work system are:

- It enhances communication and coordination among the parties involved in the work activity.

- Identifying and controlling the hazards and risks reduces the likelihood of accidents, incidents, and injuries.

- It improves the quality and efficiency of the work by providing clear guidelines and expectations.

- It facilitates compliance with legal and regulatory requirements and industry standards.

- It records the work history and performance for future reference and improvement.

How to Implement a Permit to Work System?

Implementing a permit-to-work (PTW) system is crucial in enhancing safety and preventing hazardous situations in various industries, particularly those involving high-risk activities. A PTW system is a formal, documented procedure that controls and authorizes specific types of work that pose potential risks to workers, equipment, or the environment. It establishes clear guidelines and responsibilities to ensure these risks are adequately identified, assessed, and mitigated before work commences. To implement a permit-to-work system in your organization, you need to:

- Establish a clear policy and procedure for issuing and managing permits.

- Define the roles and responsibilities of the permit issuer, approver, holder, receiver, and supervisor.

- Provide adequate training and awareness for all the staff involved in the permit system.

- Develop standard templates and forms for different types of permits.

- Implement a system for tracking and auditing permits.

- Monitor, Review and update the permit system periodically.

Establish a clear policy and procedure for issuing and managing permits.

This should include the permit system’s scope, objectives, benefits, and the criteria and conditions for issuing permits. The policy and procedure should also specify the roles and responsibilities of the staff involved in the permit system, such as the permit issuer, approver, holder, receiver, and supervisor.

- Establish clear and detailed procedures for issuing, reviewing, approving, and closing out PTWs.

- Define the roles and responsibilities of personnel involved in the PTW process, including the permit issuer, permit approver, and workers.

- Outline the steps involved in obtaining, implementing, and returning PTWs.

Define the roles and responsibilities of the permit issuer, approver, holder, receiver, and supervisor.

Clearly define the roles and responsibilities of individuals involved in the PTW process. This includes the permit issuer, permit requester, permit coordinator, and any additional personnel involved in risk assessment and authorization.

The permit issuer authorizes the work to be done and issues the permit. The permit approver reviews and approves the permit before it is issued. The permit holder performs the work under the permit. The permit receiver accepts the work from the permit holder. The supervisor oversees and monitors the work under the permit.

Provide adequate training and awareness for all the staff involved in the permit system.

The staff should be trained to use and comply with the permit system, identify and manage hazards and risks associated with the work, and be aware of their roles and responsibilities and the consequences of not following the permit system.

- Provide comprehensive training to all personnel involved in the PTW process, including workers, supervisors, and management.

- Ensure everyone understands the purpose of the PTW system, their roles and responsibilities, and the procedures for obtaining and utilizing PTWs.

- Emphasize the importance of following PTWs strictly to control hazards and prevent accidents.

- Emphasize hazard identification, risk assessment, control measures, and emergency response protocols.

Develop standard templates and forms for different types of permits.

Depending on the nature and complexity of the work, different types of permits may be required, such as hot work permits, confined space entry permits, electrical isolation permits, etc. Create standardized permit forms that clearly outline the work, the hazards involved, and the required control measures. These forms should include sections for job details, risk assessment, control measures, authorizations, and emergency procedures.

The templates and forms should include all the relevant information and instructions for each type of permit, such as the scope, duration, location, hazards, precautions, emergency procedures, etc.

- Create standardized PTW forms that are easy to understand and complete.

- Include essential information such as job description, hazard identification, risk control measures, emergency procedures, and required signatures.

- Adapt PTW forms to specific work activities, ensuring they capture the relevant hazards and controls.

Implement a system for tracking and auditing permits.

This should include a mechanism for recording, storing, retrieving, and disposing of permits. The system should also allow for regular audits and inspections of the permits to ensure compliance and effectiveness. The audits and inspections should identify gaps or weaknesses in the permit system and recommend corrective actions.

- Integrate the PTW system into the organization’s overall safety management system.

- Make PTW forms readily accessible and easy for authorized personnel to obtain.

- Establish a clear communication channel for reporting hazards and incidents related to PTW activities.

Implement Pre-Work Planning and Risk Assessment: Thorough pre-work planning and risk assessment are required for all hazardous activities. This involves identifying hazards, evaluating risks, and implementing appropriate control measures to mitigate those risks.

Issue and Authorize Permits: Establish a straightforward process for issuing and authorizing permits. This may involve a review by designated personnel, such as safety officers or supervisors, to ensure that the proposed work activities and control measures are adequate.

Conduct Worksite Inspections: Implement regular worksite inspections to verify that the work being conducted adheres to the approved PTW and that the required control measures are effective.

Monitor, Review and update the permit system periodically.

The permit system should be reviewed and updated at least annually or whenever there are changes in legislation, standards, technology, or work practices. The review should evaluate the permit system’s performance and outcomes and identify any areas for improvement or enhancement.

- Regularly review PTW records to identify trends, potential issues, and areas for improvement.

- Audits and inspections are conducted to assess the effectiveness of the PTW system and ensure compliance with procedures.

- Continuously update and refine the PTW system based on feedback, lessons learned, and work activities or hazards changes.

Investigate Permit Deviations and Incidents: Promptly investigate any deviations from the PTW or incidents during permitted work activities. Use these investigations to identify areas for improvement and prevent similar occurrences.

Continuously Review and Update: Regularly review and update the PTW system to reflect work procedures, equipment, or regulatory requirements changes.

A permit-to-work system is a valuable tool for enhancing safety and efficiency in your organization. By following these steps, you can implement a system that suits your needs and meets your objectives.

What are the components of a work permit?

The components of a work permit vary depending on the specific type of work and the jurisdiction in which it is being carried out. Still, typically, a work permit will include the following information:

- Purpose: A description of the work to be carried out, including the location, scope, and duration. Determine the scope of work.

- Hazards: An assessment of the hazards associated with the work, including identifying the risks and the measures in place to control those risks. Conduct a thorough hazard assessment as written on the permit.

- Authorization: The signature or approval of a designated individual, such as a supervisor or manager, indicating that the work is authorized to proceed.

- Restrictions: Any restrictions or limitations on the work, such as the use of specific equipment or materials, the need for specific personal protective equipment, or the requirement for a particular number of workers to be present.

- Emergency procedures: A description of the emergency procedures to be followed in the event of an accident, incident, or emergency, including the identification of the responsible party and the procedure for contacting emergency services.

- Certificates: A list of any relevant documentation or certificates, such as safety procedures, training records, equipment maintenance records, isolation certificates, or inspection reports.

- Signatures of workers: The signatures of the workers carrying out the work indicate that they have read and understood the permit, the hazards involved, and the measures in place to control those hazards.

These are the main components of a work permit. Still, depending on the type of work and the jurisdiction in which it is being carried out, other information may also be required, such as the names of the workers involved, the date and time of the work, or the status of any relevant permits or licenses. The specific components of a work permit will depend on the nature of the work, the hazards involved, and the requirements of the relevant jurisdiction.

What are the different types of work permits?

Several types of work permits are designed to control and manage specific types of hazardous or potentially hazardous work activities. Here are some of the most common types of work permits:

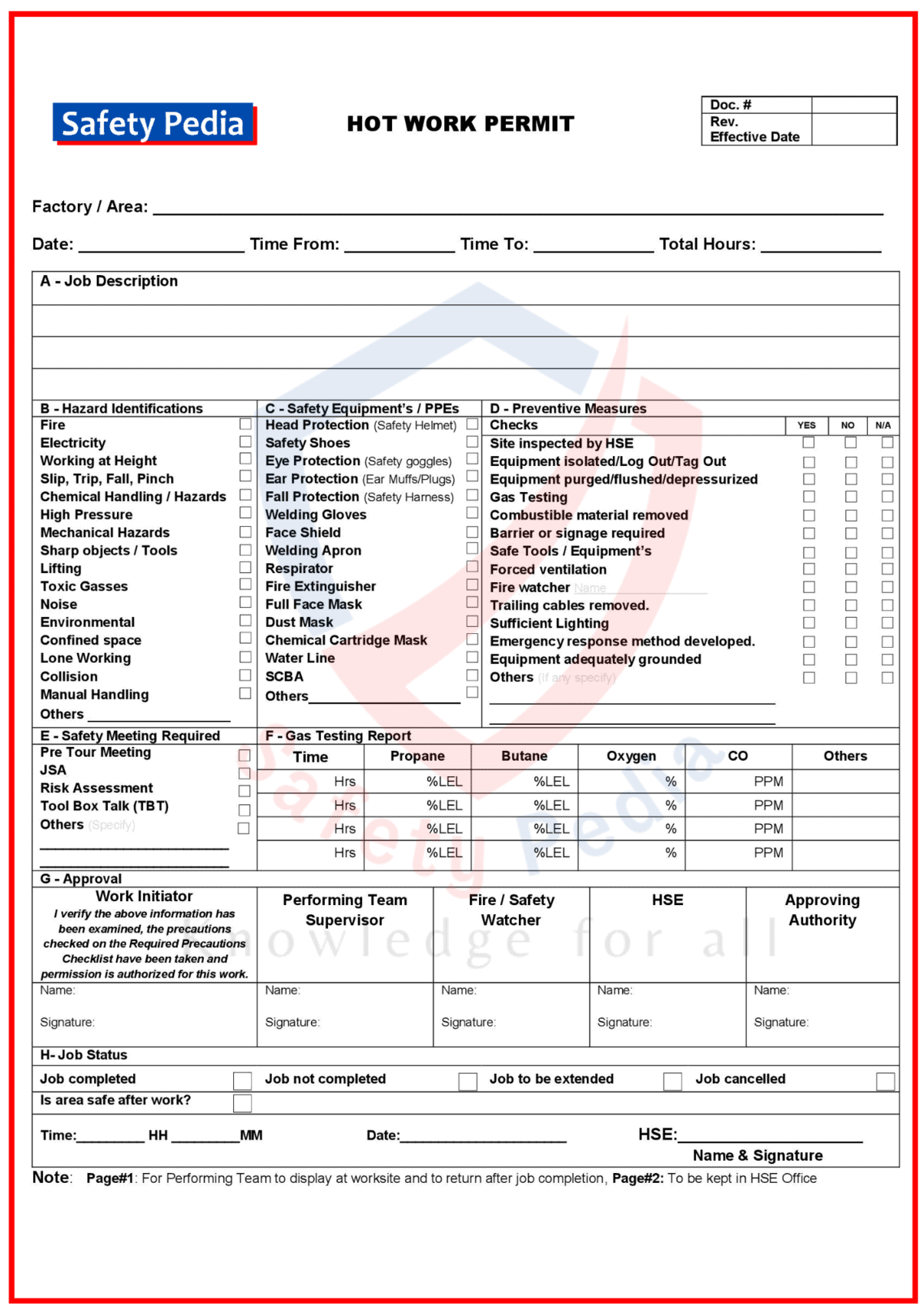

Hot Work Permit:

This type of permit authorizes work that involves open flames, sparks, or heat-producing processes, such as welding, cutting, or soldering.

Confined Space Permit:

This type of permit is used to authorize work in a confined space, such as a tank, pipe, or silo. Confined spaces pose unique hazards, such as limited access, poor ventilation, and the risk of toxic atmospheres. A permit is required to ensure workers are appropriately trained and equipped to carry out the work safely.

Electrical Work Permit:

This type of permit authorizes work on electrical systems or equipment, such as electrical installations, repairs, or maintenance. The permit outlines the necessary precautions and safety measures to protect workers from electrical hazards.

Excavation Permit:

This type of permit authorizes work that involves digging or excavation, such as trenches, pits, or holes. Excavation work poses the risk of cave-ins, so a permit is required to ensure that workers are appropriately trained and equipped to carry out the work safely.

Lifting Operations Permit:

This type of permit authorizes work involving cranes, hoists, or other lifting equipment. Lifting operations can be hazardous, so a permit is required to ensure workers are appropriately trained and equipped to carry out the work safely.

High-Risk Work Permit:

This type of permit authorizes work that involves higher-risk activities, such as working at heights, with hazardous substances, or in hazardous environments. The permit outlines the necessary precautions and safety measures to protect workers from these risks.

Radiation Work Permit:

This type of permit authorizes work involving exposure to ionizing or non-ionizing radiation, such as X-rays or radioactive materials. Radiation work poses significant health risks, so a permit is required to ensure that workers are adequately trained and equipped to do the job safely and follow radiation protection regulations.

These are just a few examples of the different work permits used in various industries. The specific types of permits required will depend on the work’s nature and the hazards involved.

Hot work permit template

Advantages and disadvantages of the work permit system

The safety permit-to-work system can have advantages and disadvantages, depending on the perspective of the individual or the organization involved.

Advantages of a permit-to-work system:

- Improved safety: A safety permit-to-work system’s main advantage is that it helps improve the safety of workers and others who may be affected by hazardous activities.

- Increased control: By requiring workers to obtain a safety permit before beginning work, the system helps to ensure that work is carried out in a controlled and safe manner, reducing the risk of accidents and incidents.

- Improved compliance: A safety permit-to-work system helps to ensure that workers are aware of the hazards associated with their work and take the necessary precautions to minimize the risk of harm.

- Documented procedures: The safety permit-to-work system provides a written record of the procedures and precautions that must be taken for specific activities, which can be helpful for training, auditing, and improving safety practices in the future.

Disadvantages of a permit-to-work system:

- Increased bureaucracy: Obtaining a safety permit can be time-consuming and bureaucratic, burdening workers and slowing the pace of work.

- Reduced flexibility: The system may not be flexible enough to accommodate the changing needs of workers or the workplace, leading to difficulties in carrying out specific tasks or adapting to new processes.

- Increased costs: Implementing a safety permit-to-work system can be expensive, including training workers, developing procedures, and monitoring compliance.

- Reduced morale: Requiring workers to obtain a safety permit before beginning work can be considered an additional burden, especially if workers feel the system is overly bureaucratic or unnecessary for their specific tasks.

Overall, the permit-to-work system can provide essential benefits in improving worker and other safety. Still, it’s vital to consider the potential drawbacks and implement the system to balance the needs of workers, employers, and the workplace.

Is a work permit not required in case of an emergency?

In workplace safety, a work permit is a document that authorizes and controls specific hazardous activities, such as working with hazardous materials or maintaining electrical equipment.

Some workplaces may make exceptions to the usual safety procedures, including the requirement for a safety work permit, to respond quickly to emergencies. However, this will depend on the emergency’s specific circumstances and the workplace’s regulations and guidelines.

It’s important to note that even in emergencies, the health and safety of workers must still be prioritized, and measures should be taken to ensure that work is carried out safely and controlled. Employers and workers should assess the risks involved and take appropriate precautions to minimize the danger to workers and others.

Do’s and dont’s of Permit-to-Work system

The “Do’s and Don’ts” of a permit-to-work system can vary depending on the specific requirements and regulations of the workplace. However, here are some general guidelines:

Do’s of a permit-to-work system:

- Clearly define the scope of work: The permit should clearly state the specific tasks that are authorized and the duration of the permit.

- Involve relevant parties: Ensure that the permit is issued and signed by authorized personnel, such as supervisors, safety officers, and workers, who have the necessary knowledge and expertise to carry out the work safely.

- Follow procedures: Follow the guidelines and precautions outlined in the permit and comply with additional requirements, such as protective equipment, isolation of hazardous areas, and equipment testing.

- Regularly review and update: Regularly review and update the permit and the procedures associated with the work to ensure that they remain relevant and effective in protecting the safety of workers and others.

Don’ts of a permit-to-work system:

- Don’t ignore the permit: Do not work without a valid permit or outside the permit’s scope.

- Don’t skip any steps: Do not skip any steps in the permit process or carry out work before the permit is issued and signed.

- Don’t use a permit for a different job: Do not use one for another job or location other than what was authorized.

- Don’t alter the permit: Do not alter or make changes to the permit without the approval of authorized personnel.

Following these “Do’s and Don’ts,” workers and employers can help ensure that the permit-to-work system is used effectively and improve workplace safety.

Can work be stopped even if a Permit to Work has been obtained?

A work activity can and should be stopped even if a Permit to Work (PTW) has been obtained if new hazards emerge, conditions change, or safety protocols are not followed. The PTW system is designed to ensure safety, and part of that responsibility is recognizing when it’s no longer safe to continue—even with a valid permit.

Situations warranting a stop might include:

- Unexpected hazards: New risks arise that weren’t identified in the initial assessment.

- Changes in conditions: Weather, environmental factors, or equipment malfunctions make the job unsafe.

- Non-compliance: Workers are not following safety measures or the specific requirements outlined in the permit.

- Near-misses or incidents: Any safety incidents during the job may indicate that work should stop for further evaluation

A well-implemented PTW system encourages supervisors and workers to prioritize safety over completing the task, emphasizing that stopping work is always an option when conditions become unsafe.

Conclusion:

A permit-to-work (PTW) system ensures workplace safety, particularly for high-risk tasks. This guide has provided an overview of what a work permit and PTW system entail, their importance, and how they are implemented to manage and mitigate risks in hazardous work environments. By establishing clear policies, defining roles, training personnel, and using structured templates and tracking mechanisms, organizations can build a robust PTW system that safeguards both workers and operations.

The components and types of work permits discussed, such as Hot Work, Confined Space, Electrical Work, etc., highlight the system’s adaptability to specific risks. While the PTW system offers many advantages in maintaining controlled work processes, it also has limitations that require careful management.

In summary, a well-maintained PTW system is essential for controlling and responsibly managing hazardous activities, even during emergencies. Adhering to established protocols, understanding the outlined “Do’s” and “Don’ts,” and actively engaging in the PTW process truly make a difference. By doing so, workplaces can facilitate a safety culture, prevent incidents, and uphold operational integrity.

It’s important to remember that a permit is just a piece of paper, It cannot ensure safety on its own if not rigorously implemented and treated with the seriousness it deserves.

References

1. https://en.wikipedia.org/wiki/Permit-to-work

Your one click can make a difference

Keep sharing and promoting health and safety awareness!

Related posts:

How to Measure Safety Performance?

Struggling to measure your workplace safety performance? Learn how to measure safety performance with key metrics to improve workplace safety. Discover essential indicators for risk assessment, compliance, and accident prevention.

The Consequences of Poor Safety Performance: Risks You Can’t Afford to Ignore

Discover the potential consequences of poor safety performance in the workplace and how they can negatively impact both employees and the company as a whole.

18 Common Challenges in Improving Safety Performance at Work

Discover 18 common challenges in improving safety performance at work. Learn how to overcome these obstacles for a safer workplace.

Join Our Safety Community!

Stay informed with the latest tips and insights on occupational health, safety, and the environment.

Hi sir how are you Does he have a Permit To Work Related Mechanic jobs Give me the job

Works

Thank you!