Introduction: Compressed Gas Cylinder Safety and Storage

Compressed gas cylinders are fundamental in various industrial, medical, and laboratory settings, housing gases critical for numerous applications. However, mishandling these cylinders poses significant hazards, including explosions, leaks, and physical injuries. Ensuring the safe storage and handling of compressed gas cylinders is paramount to prevent accidents and maintain a secure working environment.

This guide on Compressed Gas Cylinder Safety and Storage provides comprehensive insights into best practices, guidelines, and protocols necessary for the proper handling, storage, and transportation of these cylinders. By adhering to these safety measures, individuals and organizations can mitigate risks, safeguard personnel, and ensure the integrity of these essential containers.

What are compressed gases?

Compressed gases can be toxic, flammable, oxidizing, corrosive, or inert. In the event of a leak, inert gases can quickly displace air in a large area creating an oxygen-deficient atmosphere, and toxic gases can create poison atmospheres. Flammable/reactive gases can result in fire and exploding cylinders. Compressed gases are often stored in compressed gas cylinders, which requires safety arrangements to prevent any incident.

According to OSHA, Compressed Gas is a gas or mixture of gases having, in a container:

- An absolute pressure exceeding 40 psi at 70°F or 21.1 °C;

- A gas or mixture of gases having, in a container, an absolute pressure exceeding 104 psi at 130°F or 54.4 °C regardless of the pressure at 70°F or 21.1°C);

- A liquid having a vapour pressure exceeding 40 psi at 100°F or 37.8°F as determined by ASTM D-323-72¹.

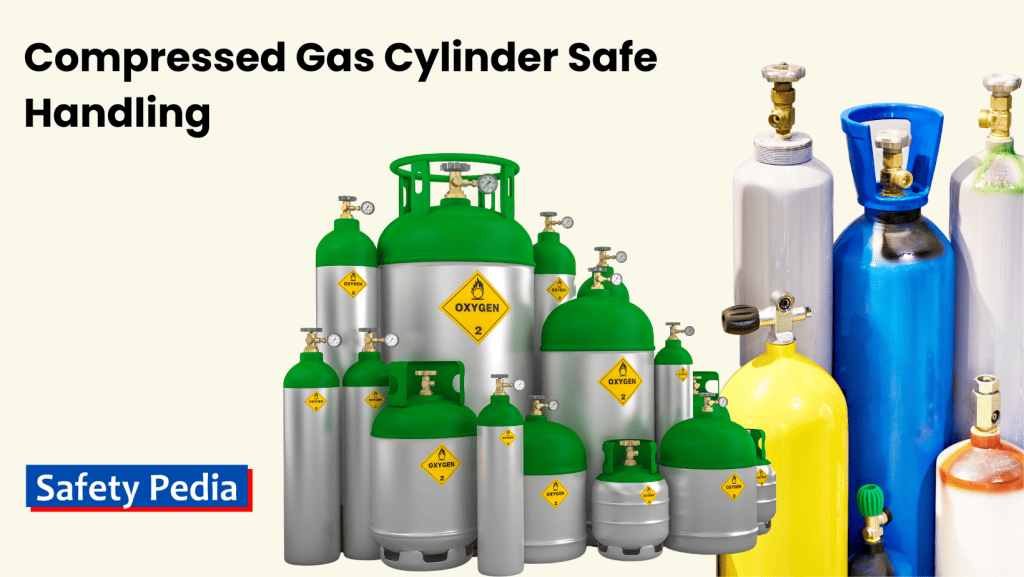

What are common gases used in Compressed gas cylinders?

Compressed gas cylinders contain various gases used across a wide range of industries and applications. Some common gases stored in compressed gas cylinders include:

- Oxygen (O2): Used in medical settings for respiratory support, in welding, cutting, and brazing applications, and in industrial processes.

- Acetylene (C2H2): Commonly used in welding due to its high-temperature flame.

- Nitrogen (N2): Used for inerting, blanketing, purging, and as a pressurizing gas in various industries, including food packaging, electronics, and oil and gas.

- Carbon Dioxide (CO2): Utilized in beverage carbonation, welding, fire extinguishers, and as a shielding gas in welding.

- Argon (Ar): Used as a shielding gas in welding, for arc welding processes, and in some industrial applications requiring an inert atmosphere.

- Hydrogen (H2): Utilized in various applications, including petroleum refining, and chemical manufacturing, and as a fuel for fuel cells and rocket propulsion.

- Helium (He): Used in cryogenics, cooling applications, as a carrier gas in gas chromatography, and in certain medical diagnostic procedures.

- Chlorine (Cl2): Employed in water treatment, sanitation, and the production of various chemicals.

- Ammonia (NH3): Used in refrigeration, fertilizer production, and in various industrial processes.

- Propane (C3H8): Commonly used as a fuel for heating, cooking, and in various industrial applications.

- R600a (Isobutane): Used as a refrigerant in domestic refrigerators, freezers, and some air conditioning systems due to its low environmental impact.

- R290 (Propane): Employed as a refrigerant in some air conditioning and refrigeration systems, known for its low global warming potential.

- R32 (Difluoromethane): Used as a refrigerant in air conditioning systems for its lower global warming potential compared to other refrigerants.

- R410A: A blend of difluoromethane (R32) and pentafluoroethane (R125), commonly used in residential and commercial air conditioning systems due to its efficient cooling properties.

These gases serve diverse purposes across industries such as healthcare, manufacturing, welding, chemical processing, and many others. Each gas has specific handling, storage, and safety requirements due to its unique properties and potential hazards. Therefore, it’s crucial to adhere to safety guidelines and proper handling procedures when dealing with compressed gas cylinders.

What are compressed gas cylinders?

Compressed gas cylinders are high-pressure containers that store gases in a compressed form. Compressed gas cylinders are widely used in general industries and construction. They are typically made of stainless steel, mild steel, and aluminum alloys. Now a day carbon fiber and composite material compressed gas cylinders are available for use.

Compressed gas cylinders are used for a variety of applications, including welding, industrial processes, gas charging, medical equipment, fire fighting services, and other activities such as scuba diving. The compressed gas is released from the cylinder through a regulator, valve or combination of both and is used as per requirement.

What are the common hazards of compressed gas?

Compressed gases can be hazardous due to the following reasons:

- Explosive or flammable gases such as propane, acetylene, or hydrogen can ignite and cause explosions if they come into contact with heat, sparks, or flames.

- An abrupt, uncontrolled discharge of cylinder contents may occur if damaged cylinders unexpectedly propel or rotate, leading to substantial injury and damage.

- Asphyxiant gases such as nitrogen or argon can displace oxygen in the air and cause suffocation or asphyxiation. This can be life-threatening if used in confined spaces.

- Corrosive gases such as chlorine or sulfur dioxide can cause chemical burns or damage tissues or equipment.

- If inhaled, toxic gases such as carbon monoxide or ammonia can cause poisoning or death.

- Cryogenic liquids, such as liquid nitrogen, can cause cold burns or freeze tissues on contact.

- Frostbite can result from exposure to extremely cold gases escaping from a cylinder. Severe cases of frostbite have the potential to cause lasting and serious damage to the skin.

- High-pressure gas can cause injury or damage if it escapes from its container or pipe or if the container fails. It can damage the ear drum and veins through the nose or eject the eyeball.

Compressed gas cylinder storage requirements

The Occupational Safety and Health Administration (OSHA) has specific requirements for storing compressed gas cylinders. OSHA’s compressed gas cylinder storage regulations can be found in 29 CFR 1910.101² and 1926.350³. Some of the requirements include the following:

- Compressed gas cylinders must be stored in an upright position and securely restrained to prevent them from falling or tipping over.

- Cylinders must be stored in a well-ventilated area away from heat sources, sparks or flames.

- Cylinders containing flammable or explosive gases must be stored in a separate, isolated area away from other materials.

- Cylinders must be protected from physical damage and corrosion and must be visually inspected regularly for signs of damage or leakage.

- Cylinders must be properly labeled and color-coded to identify the type of gas they contain.

- Compressed gas cylinders must be handled and transported in a safe manner, using appropriate equipment, such as hand trucks or cylinder trolleys.

- Access to compressed gas cylinder storage areas must only be restricted to authorized personnel.

Compressed gas signage

Compressed gas signage is used to identify the presence of compressed gases and their contents. It provides information about the specific hazards that are associated with those gases. The following types of signs are commonly used:

- Identification signs: These signs are used to identify the specific type of gas present in a cylinder or container. Identification signs are labels that typically include the name of the gas, its chemical symbol, and the NFPA diamond. For example, a label may indicate the presence of Oxygen (O2).

- Hazard warning signs: These signs are used to alert workers and other individuals about the presence of compressed gas and hazardous materials and to warn of the specific dangers associated with those materials. For example, a sign may indicate the presence of flammable gases or toxic gases. These signs are used to indicate a specific danger or hazard associated with a gas. For example, a sign may indicate the risk of suffocation if a gas displaces oxygen.

- Supplier Information: Manufacturer or Supplier information is necessary on the cylinder to know the contact information. They can be contacted in case of a requirement or any emergency.

- Emergency response signs: These signs provide information about what to do in case of an emergency, such as a gas leak. They may include information on the location of emergency equipment, such as fire extinguishers, or on the procedures to follow in case of an emergency.

Note: Compressed gas signage should be easily visible, durable, and understandable to all personnel who may be exposed to the hazards associated with the compressed gases. The signs should comply with applicable regulations and standards, such as OSHA regulations, local regulations, or industry standards.

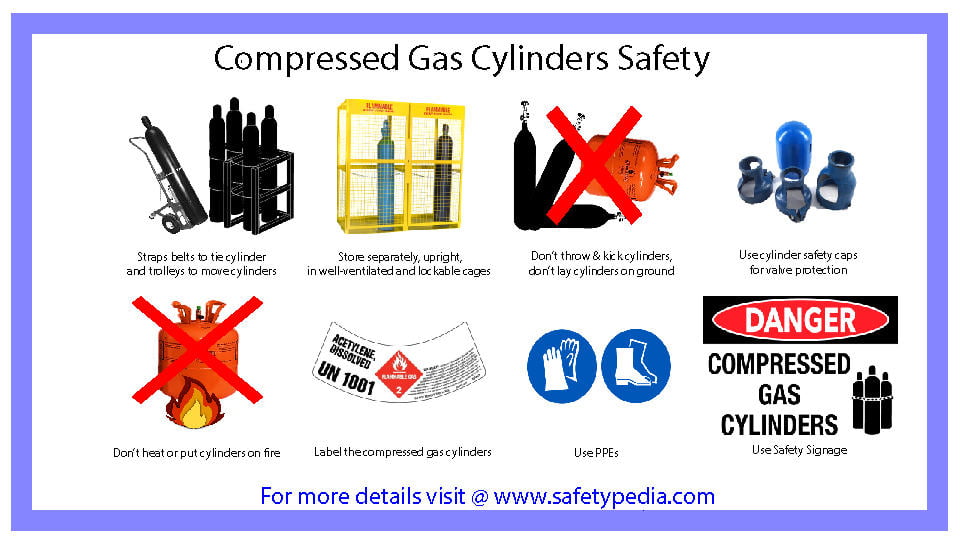

Compressed gas cylinder safe handling

Compressed gas cylinders can pose significant safety hazards if not handled safely. Here are some general safety tips for handling compressed gas cylinders:

- Read the label: Before handling any compressed gas cylinder, read the label and become familiar with the hazards associated with the gas.

- Use proper equipment: Use equipment specifically designed for handling compressed gas cylinders, such as hand trucks or cylinder trolleys, to transport the cylinders.

- Store securely: Store compressed gas cylinders in an upright position, securely restrained to prevent tipping or falling. Store flammable or explosive gases in a separate, isolated area away from other materials. Fasten the cylinder with straps to prevent falling or toppling.

- Avoid heat sources: Do not store or use compressed gas cylinders near heat sources, sparks, or flames. The temperature rise can cause an explosion.

- Inspect regularly: Regularly inspect compressed gas cylinders for signs of damage or leakage, such as dents, rust, loss of weight, or discoloration.

- Properly ventilate: Use compressed gas cylinders in a well-ventilated area to reduce the risk of exposure to toxic or asphyxiant gases. Instal gas sensors to generate alarms in case of gas leakage.

- Use caution when opening: Use caution when opening compressed gas cylinders. Open the valve slowly and follow the manufacturer’s instructions.

- Wear appropriate personal protective equipment: Wear gloves, eye protection, and other appropriate personal protective equipment when handling compressed gas cylinders, especially use gas masks when working with toxic or corrosive gases.

- Follow emergency procedures: In case of a gas leak or other emergency, follow established emergency procedures, evacuate the area if necessary, and call emergency response teams for assistance.

Do’s & Dont’s for storing compressed gas cylinders

Do’s:

- Store cylinders in an upright position, securely restrained to prevent tipping or falling.

- Store flammable or explosive gases in a separate, isolated area away from other materials.

- Store cylinders in a well-ventilated area to reduce the risk of exposure to toxic or asphyxiant gases.

- Label and color-code cylinders to identify the type of gas they contain.

- Regularly inspect cylinders for signs of damage or leakage, such as dents, rust, or discoloration.

- Follow all applicable regulations and industry standards, such as OSHA regulations or NFPA standards.

Dont’s:

- Don’t store or use compressed gas cylinders near sources of heat, sparks, or flames.

- Don’t store cylinders in a horizontal position or in a place where they may be subject to impact or physical damage.

- Don’t store full and empty cylinders together.

- Don’t attempt to repair or modify a damaged or leaking cylinder.

- Don’t use a cylinder if it is damaged or shows signs of leakage.

- Don’t exceed the pressure limits specified by the manufacturer or OSHA regulations.

Storing oxygen and acetylene cylinders

Storing oxygen and acetylene cylinders requires special considerations to ensure safe and secure storage. Here are some general tips for storing oxygen and acetylene cylinders:

- Store in separate, well-ventilated areas: Store oxygen and acetylene cylinders in separate, well-ventilated areas to prevent the buildup of flammable or explosive gases.

- Store in an upright position: Store oxygen and acetylene cylinders in an upright position, securely restrained with straps to prevent tipping or falling.

- Label and color-code the cylinders: Label and color-code the cylinders to identify the type of gas they contain.

- Avoid heat sources: Store the cylinders away from heat sources, sparks, or flames.

- Use proper cylinder storage racks: Use proper cylinder storage racks or cabinets to store the cylinders. The racks or cabinets should be sturdy, secure, and capable of supporting the weight of the cylinders.

- Use cylinder regulators: Use cylinder regulators to control the gas flow from the cylinder and reduce the gas pressure before use.

Remember, oxygen and acetylene are reactive gases that pose significant safety hazards if not handled and stored properly.

Cylinder Valve Protection

Cylinder valve protection refers to measures taken to protect the valve of a compressed gas cylinder from damage or tampering. The following are some common methods of protecting cylinder valves:

- Valve protection caps: These are metal or plastic caps placed over a cylinder’s valve when it is not in use. The cap helps to prevent accidental damage to the valve and to keep it clean and free of debris.

- Valve protection guards: These are metal or plastic guards installed around the cylinder’s valve to protect it from damage. The guard helps to prevent accidental impact on the valve and can also provide a barrier to unauthorized access.

- Valve protection chains are chains or straps attached to the cylinder and the valve to prevent the cylinder from being knocked over or otherwise damaged. The chain helps to prevent accidental damage to the valve and to keep the cylinder secure.

- Lock-out devices: These are locks or other devices that can be used to secure the valve of a cylinder to prevent unauthorized access or tampering. The lock-out device helps to prevent accidental discharge or release of the gas and to ensure that only authorized personnel can access the cylinder.

- Valve protection sleeves: These are made of plastic or other materials that can be fitted over the cylinder’s valve to provide additional protection against damage or tampering.

Valve protection is important because the valve is a critical component of the compressed gas cylinder and is responsible for controlling gas flow. Proper protection helps to prevent accidental damage, leakage, or release of gas, which can pose significant safety hazards.

Transporting compressed gas cylinders

Transporting compressed gas cylinders requires proper planning and precautions to ensure the safe handling and transportation of the cylinders. Here are some general tips for transporting compressed gas cylinders:

- Use proper equipment: Use equipment specifically designed for handling compressed gas cylinders, such as hand trucks or trollies, to transport the cylinders.

- Secure the cylinders: Secure the cylinders to prevent tipping or falling during transportation. Use chains, straps, or other restraints to keep the cylinders upright.

- Label and color-code the cylinders: Label and color-code the cylinders to identify the type of gas they contain.

- Follow all regulations and standards: Follow all applicable regulations and industry standards, such as OSHA regulations or DOT requirements, for the transportation of compressed gas cylinders.

- Avoid heat sources: Avoid exposing the cylinders to heat sources, sparks, or flames during transportation.

- Wear appropriate personal protective equipment: Wear gloves, eye protection, and other appropriate personal protective equipment when handling compressed gas cylinders, especially when working with toxic or corrosive gases.

- Use caution when loading and unloading: Use caution when loading and unloading compressed gas cylinders to prevent accidental damage or injury.

- Transport only approved gases: Only transport gases that have been approved for transportation by the relevant authorities, such as the DOT.

Compressed gas cylinders safety checklist

| Sr # | Particulars | Yes | No | Not Applicable | Remarks |

|---|---|---|---|---|---|

| 1 | Is the regulator compatible with the type and pressure of gas in the cylinder? | ||||

| 2 | Are regulators and valves inspected for damage or wear before connection and use? | ||||

| 3 | Are valve protection caps/covers in place when cylinders are not in use? | ||||

| 4 | Are safety pressure relief valves available for compressed gas cylinders? | ||||

| 5 | Are cylinders properly secured with straps/belts/chains during transportation to prevent rolling or falling? | ||||

| 6 | If point 17 is not applicable then, Is there a separate fire-resistant barrier available? | ||||

| 7 | Is there any sign of leakages observed? | ||||

| 8 | Are compressed gas cylinders Kept away from heat and open flames? | ||||

| 9 | Are cylinders stored in a well-ventilated, dry, cool, and secure area? | ||||

| 10 | Are cylinders stored away from heat, sparks, flames, and incompatible materials? | ||||

| 11 | Are the cylinders stored in a manner that prevents or minimizes rust formation? | ||||

| 12 | Are the cylinders stored in a manner that prevents or minimizes corrosion? | ||||

| 13 | Is there any type of tampering with compressed gas cylinders such as label, seal, valve or pressure relief valve found? | ||||

| 14 | Are cylinders stored upright and secured with chains or straps to prevent tipping or falling? | ||||

| 15 | Are cylinders positioned in an area that minimizes the risk of being struck or colliding with other objects? | ||||

| 16 | Are cylinders well protected against any falling objects? | ||||

| 17 | Are oxygen cylinders kept at least 20 feet away from flammable gases or liquids? | ||||

| 18 | Are personal protective equipment (PPE) available such as gloves, goggles, and shoes when handling cylinders | ||||

| 19 | Are cylinders stored away from electrical connections or any source of ignition? | ||||

| 20 | Are incompatible gases stored separately to avoid potential chemical reactions? | ||||

| 21 | Are flammable gases stored away from oxidizing gases? | ||||

| 22 | Are full cylinders labeled and stored away from empty cylinders? | ||||

| 23 | Are cylinders clearly labeled with the gas contents, hazard warnings, and pressure ratings? | ||||

| 24 | Are labels and markings legible and not defaced or hidden? | ||||

| 25 | Is a safety data sheet (SDS) available? | ||||

| 26 | Have the disposal of empty or unwanted cylinders according to local regulations and the supplier’s instructions available? | ||||

| 27 | Has the operator read the manufacturer’s instructions and is aware of the physical and health hazards, flammability, reactivity, and toxicity of the gas? | ||||

| 28 | Have personnel received proper training in handling, storage, transportation, use, and disposal of compressed gas cylinders? | ||||

| 29 | Are cylinders transported using appropriate hand trucks designed for cylinder transport? | ||||

| 30 | Are safety signs displayed at visible locations to communicate hazards and necessary cautions? | ||||

| 31 | Are cylinders properly secured with straps/belts/chains during transportation to prevent rolling or falling? | ||||

| 32 | Is there an emergency plan in place, including procedures for evacuations and containment of leaks? | ||||

| 33 | Is the storage area labeled as “Compressed Gas Cylinders Storage Area”? | ||||

| 34 | Is a third-party testing certificate for hydrotesting, and interior testing available? | ||||

| 35 | Have personnel received proper training in handling, use, storage, transportation, and disposal of compressed gas cylinders? | ||||

| 36 | Is there proper documentation of cylinder inspections, maintenance, and training records? | ||||

| 37 | Are cylinders properly secured with straps/belts/chains during transportation to prevent rolling or falling? |

How to Respond to a Compressed Gas Cylinder Accident?

Compressed gas cylinders are useful but dangerous tools that require proper handling and storage. By following some basic safety rules and knowing how to respond to emergencies, you can reduce the risk of accidents and injuries involving compressed gas cylinders.

Safety First Protect Yourself From Dangers:

- Ensure personal safety by donning appropriate protective gear (safety glasses, gloves, etc.) before approaching the accident scene.

- Evacuate the area if there’s a risk of fire, explosion, or exposure to hazardous gases.

Alert Others and Call for Help:

- Notify others in the vicinity about the accident and instruct them to stay away from the area.

- Contact emergency services, including medical assistance and the fire department, if necessary.

Isolate the Area:

- Create a safe perimeter around the accident site to prevent unauthorized access and further risks.

- If possible and safe to do so, shut off the gas supply by closing the cylinder valve, if it’s leaking and you’re trained to handle it.

Evacuate and Ventilate:

- Evacuate everyone from the affected area to a safe location.

- If indoors, open windows and doors to allow ventilation and dissipate any released gas.

Reporting and Document the Incident:

- Report the incident to the supplier, and relevant authorities within your organization and follow established reporting procedures.

- Record details of the accident, including the time, location, involved individuals, actions taken, and any observed damages.

- Maintain accurate documentation for future reference and investigation purposes.

Assist the Injured (If Any):

- If there are injuries, provide immediate first aid or medical attention if you’re trained to do so without putting yourself at risk.

- Do not attempt to treat injuries beyond your level of training.

Professional Assessment and Cleanup:

- Engage professional services to assess the situation, repair any damaged equipment, and properly dispose of damaged cylinders or gas residues.

If

Gas Leak Occurred:

A gas leak from a cylinder can cause asphyxiation, fire, explosion, or poisoning, depending on the type and amount of gas released. If you notice a gas leak from a cylinder, you should follow these steps:

- Immediately evacuate the area and alert others nearby.

- Shut off the gas supply from the main valve if possible and safe to do so.

- Remove ignition sources from the immediate vicinity, if any

- Do not use any electrical equipment or create sparks.

- Contact emergency services and alert them about the gas leak.

- If you have been exposed to a toxic or corrosive gas, seek medical attention as soon as possible.

Gas Cylinder Valve Broke Due to Hit or Collision:

A broken valve can cause a rapid release of gas from the cylinder, creating a jet effect that can propel the cylinder or its fragments at high speed. This can cause serious injuries or damage to property. If you witness a broken valve accident, you should follow these steps:

- Stay away from the cylinder and its trajectory and take cover behind a solid object.

- Do not attempt to stop or catch the cylinder or its fragments.

- Evacuate the area if there’s a risk of further damage or leaks.

- Ensure everyone stays away from the damaged cylinder.

- Call the emergency services and inform them of the situation and the type of gas involved.

- Do not approach the cylinder until it is secured by the authorities.

Fire Occurred at Flammable Gas Cylinder:

A fire involving a flammable gas cylinder can cause an explosion or a rapid increase in pressure that can rupture the cylinder. If you encounter a fire at a flammable gas cylinder, you should follow these steps:

- Do not attempt to extinguish the fire if it involves a flammable gas cylinder unless you are trained and equipped to handle such fires.

- Evacuate the area immediately and alert nearby.

- Call the emergency services and inform them of the situation and the type of gas involved.

- Use appropriate fire extinguishers only if it’s safe to do so and you’re trained in handling fires related to gas cylinders.

- Do not re-enter the area until it is declared safe by the authorities.

Explosion Happens:

An explosion involving a compressed gas cylinder can result from various causes, such as overfilling, overheating, corrosion, or external impact. An explosion can cause severe injuries, fatalities, or damage to property. If you experience an explosion involving a compressed gas cylinder, you should follow these steps:

- Protect yourself from flying debris and shock waves by lying down on the ground and covering your head with your arms.

- Take cover immediately behind a sturdy object or seek shelter under tables or benches if available.

- Evacuate the area as soon as it’s safe to do so and move to a safe point.

- Call the emergency services and inform them of the situation and the type of gas involved.

- Check for injuries and provide first aid to those in need.

Asphyxiant Gas Leak Occurred:

An asphyxiant gas is a gas that displaces oxygen in the air and can cause suffocation or unconsciousness. Examples of asphyxiant gases include nitrogen, helium, argon, and carbon dioxide. If you suspect an asphyxiant gas leak from a cylinder, you should follow these steps:

- Leave the area immediately to get fresh air in a well-ventilated location.

- Alert others nearby and prevent them from entering the area.

- Do not re-enter the area until it’s deemed safe.

- If someone is affected, provide assistance if you’re trained in first aid without endangering yourself.

Handler Got Frostbite Due to Leaking Hose:

A leaking hose from a compressed gas cylinder can cause frostbite or cold burns due to the low temperature of the escaping gas. This can damage the skin or underlying tissues and cause pain, numbness, or blisters. If you or someone else suffers from frostbite due to a leaking hose, you should follow these steps:

- Stop the gas flow from the hose if possible and safe to do so.

- Remove any clothing or jewelry that may restrict blood circulation in the affected area.

- Move the affected person to a warmer area immediately.

- Warm up the affected area gradually with warm water or a warm cloth. Do not use hot water or direct heat sources, as this may cause further damage.

- Do not rub or massage the affected area, as this may cause skin damage or infection.

- Seek medical attention promptly for frostbite treatment.

In all situations involving compressed gas cylinder accidents, prioritize personal safety, evacuate the area if necessary, and seek professional assistance immediately. Only take action if you’re trained and it can be done without putting yourself or others at risk.

Remember, dealing with compressed gas cylinder accidents requires expertise and training. If you’re not adequately trained or equipped to handle the situation, prioritize your safety and seek assistance from qualified professionals immediately.

Conclusion:

Remember, the safety of compressed gas cylinders is critical and must be taken seriously. These tips are not exhaustive, and specific safety measures may vary depending on the gas type and situation. It is essential to follow all applicable regulations and industry standards. It is important to receive proper training on the safe handling and storage of these gases and to follow established procedures and guidelines. Provide safety training on the safe handling and use of compressed gas cylinders to operators and their supervisors. It is important to note that these safety precautions may vary depending on the specific industry and the types of hazardous substances involved. It is crucial to follow all applicable regulations and industry standards to ensure a safe working environment in an explosive atmosphere.

References