What is an Explosive Atmosphere?

The term ATEX refers to the hazard of explosive atmospheres in the workplace due to the mixture of dangerous substances like flammable gasses, vapor, mist, or combustible dust with air under certain atmospheric conditions that can be ignited by a source of ignition resulting in an explosion.

A specific fuel-to-air mixture ratio makes the explosive atmosphere where the ignition can result in an explosion. In case of ignition to a flammable explosive atmosphere, the fire can quickly reach to unburnt mixture creating a fireball and producing high heat and shock waves. Loss of life, severe injury, or significant damages can be the consequences of an explosion. Such environments can be found in various industries, including oil and gas, petrochemical, chemical, and grain handling. To prevent explosions, special measures must be taken to eliminate sources of ignition and to control the mixture of dangerous substances.

At various workplaces, hazardous substances are part of the process, If these hazardous substances can create an Explosive Atmosphere, which requires conformity to ATEX standards, then the minimum requirements to prevent the risk of fire and explosion are stated below:

- Carryout a risk assessment

- All electrical equipment must meet ATEX conformity.

- Use non-sparking tools.

- Fixed gas/dust detection sensors.

- Lower Explosive Limits (LEL) detectors for mobile gas testing.

- Machine equipment, pipelines, tanks, or connected metal parts must be grounded.

- Wear an anti-static uniform and shoes.

- Remove your body charge using static charge removal devices before

- entering an explosive atmosphere.

- Restrict entry to authorized persons only.

- Restrict vehicle entry.

- Staff must be well trained.

- Hot works must be subjected to a permit to work.

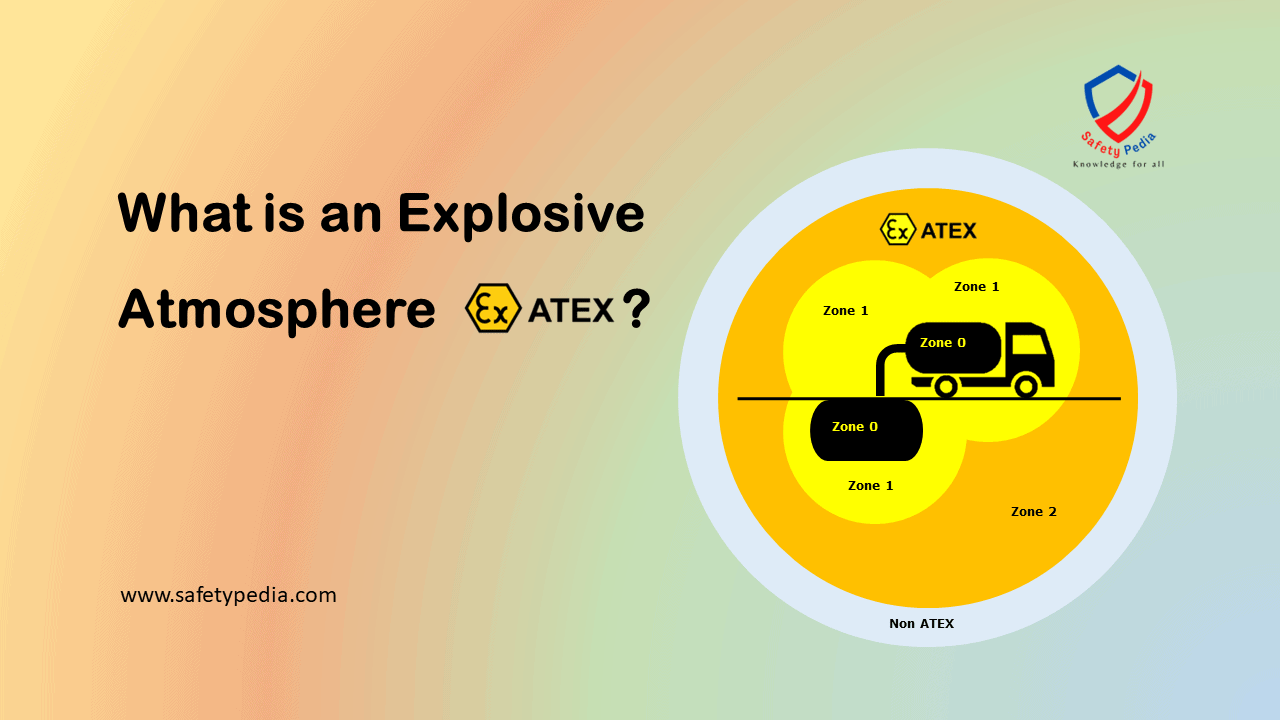

Hazardous area classification

Hazardous area classification is a critical part of ensuring safety in locations where explosive atmospheres may be present. It involves categorizing areas based on the likelihood of explosive atmospheres and the types of flammable substances. Two common classification systems are Zone classification (used in Europe and internationally, often referred to by the ATEX directive) and Division classification (used in North America, specified in the NEC or National Electrical Code).

Here’s an overview of both systems:

Zone Classification (ATEX):

- ATEX (Atmosphères Explosibles) is a European directive that sets the standards for equipment used in potentially explosive atmospheres.

- Zone classification divides hazardous areas into three zones based on the frequency and duration of the presence of explosive atmospheres:

Zone 0: An area where explosive atmospheres are present continuously or for long periods.

Zone 1: An area where explosive atmospheres are likely to occur occasionally during normal operation.

Zone 2: An area where explosive atmospheres are not likely to occur, or if they do, only for a short time. - ATEX also categorizes equipment and materials suitable for each zone and defines requirements for equipment and safety measures.

Division Classification (NEC):

- The National Electrical Code (NEC), primarily used in the United States, employs a Division classification system to designate hazardous areas.

- Division classification divides hazardous locations into two divisions:

Division 1: An area where ignitable concentrations of flammable gases, vapors, or dusts are likely to exist under normal operating conditions or frequently due to repair or maintenance.

Division 2: An area where ignitable concentrations of flammable substances are not likely to exist during normal operations, and if they do, they will exist for a short duration. - The NEC provides specific requirements for electrical equipment in each division, focusing on preventing the ignition of potentially explosive atmospheres.

Key Differences:

- Geographic Variation: ATEX is widely recognized and used in Europe and various parts of the world, while NEC and Division classification are primarily used in North America.

- Terminology: The terminology and designations for hazardous zones or divisions differ between the two systems. For example, Zone 0 in ATEX corresponds to Division 1 in NEC.

- Regulatory Framework: ATEX is a directive, and compliance with ATEX standards is required in Europe, while the NEC is a national code followed in the United States.

- Application: While the primary focus is on electrical equipment and installations, both systems are relevant for non-electrical equipment and safety measures in hazardous areas.

It’s important for businesses and organizations to understand and apply the appropriate classification system based on their geographic location and regulatory requirements to ensure safety in hazardous areas. Proper classification helps in the selection and installation of suitable equipment and safety measures to mitigate the risks of explosive atmospheres.

Consequences of Explosive Atmospheres

- Physical damage

- Human injury and fatalities

- Environmental impact

ATEX Zones

| Zone Classification Description, A place in which an explosive atmosphere is: | Gases or Vapors like Propane, Butane or etc. | Dust like powder paint, carbon dust or etc. |

| present continuously for long periods | Zone 0 | Zone 20 |

| likely to occur in normal operation | Zone 1 | Zone 21 |

| is not likely to occur in normal operation but, if it does occur, will persist for a short period only | Zone 2 | Zone 22 |

Working in an explosive atmosphere can be extremely dangerous and requires strict safety measures to be taken to prevent accidents and explosions. Some of the safety precautions that should be followed when working in an explosive atmosphere include:

- Conducting a risk assessment: Before starting any work, it is important to conduct a thorough risk assessment to identify potential hazards and sources of ignition.

- Implementing appropriate explosion protection measures: This can include installing explosion-proof equipment, using explosion-proof electrical equipment, and ensuring that all equipment is properly grounded.

- Proper ventilation: Adequate ventilation should be provided to prevent the buildup of explosive atmospheres.

- Restrict Boundary: Make sure to define the boundary of the plant and equipment or the place where the explosive atmosphere is likely to occur to restrict unwanted entries. Only authorized personnel shall be allowed to enter.

- Using appropriate personal protective equipment (PPE): This includes fire-resistant clothing, hard hats, safety glasses, and other protective equipment specific to the task being performed.

- Implementing good housekeeping practices: This includes keeping work areas clean, free from accumulations of hazardous substances, and safely storing flammable liquids and materials.

- Proper training: All personnel working in an explosive atmosphere must be properly trained in the hazards associated with the work, safe work practices, and emergency procedures.

- Establishing emergency response procedures: In the event of an emergency, it is essential to have a well-defined and tested emergency response plan in place. Emergency alarm mechanisms and compatible fire-fighting equipment must be easily accessible.

It is important to note that these safety precautions may vary depending on the specific industry and the types of hazardous substances involved. It is crucial to follow all applicable regulations and industry standards to ensure a safe working environment in an explosive atmosphere.

What can cause an explosive atmosphere?

There are many different things that can cause an explosive atmosphere, including:

- Leaks from pipes and equipment

- Spills and splashes

- Dust from manufacturing processes

- Natural gas and other flammable gases

- Vapors from gasoline, solvents, and other liquids

- Aerosols

Where are explosive atmospheres found?

Explosive atmospheres are found in many workplaces where flammable substances are used, stored or processed, including:

Industrial Facilities:

- Chemical Plants: Chemical manufacturing facilities often handle volatile and flammable chemicals, creating the potential for explosive atmospheres.

- Petrochemical Refineries: Oil refineries deal with various flammable hydrocarbons, making them susceptible to explosive atmospheres.

- Pharmaceutical Manufacturing: The production of pharmaceuticals may involve the use of flammable solvents and powders.

- Food and Beverage Production: Certain food processing operations, like grain handling and grain mills, can produce explosive dust atmospheres.

- Paint and Coating Operations: Facilities that use flammable paints, solvents, and coatings can pose explosion risks.

- Mining and Extractive Industries: Underground mining and drilling operations can encounter explosive atmospheres due to the presence of gases and dusts.

- Woodworking and Sawmills: Wood dust generated during cutting and milling processes can form explosive atmospheres.

Laboratories:

- Research Laboratories: Laboratories working with flammable chemicals, solvents, and gases can have areas at risk of explosion.

- Chemical Storage Facilities: Storage areas for flammable chemicals need careful ventilation and safety measures to prevent explosive atmospheres.

Oil and Gas Facilities:

- Oil Drilling Rigs: Offshore and onshore drilling sites have the potential for explosive atmospheres due to the presence of flammable hydrocarbons.

- Natural Gas Processing Plants: Natural gas processing facilities handle flammable gases.

- Gasoline Stations: The storage and dispensing of gasoline and other fuels pose explosion risks.

Manufacturing Plants:

- Automotive Manufacturing: Paint booths, fuel storage, and welding operations can create explosive atmospheres.

- Electronics Manufacturing: Some processes, such as foaming, may involve flammable substances.

- Metalworking: Metal dust generated during machining and grinding can lead to explosive dust atmospheres.

Utilities:

- Power Plants: Power generation facilities, including coal-fired and gas-fired power plants, handle flammable fuels and dusts.

- Natural Gas Distribution: Natural gas pipelines and compressor stations can have explosive atmospheres.

Hazardous Locations:

- Classified Areas: Locations classified as hazardous areas according to zoning and classification systems (e.g., ATEX, NEC) in which explosive atmospheres are likely to occur. These include zones in proximity to flammable substances.

Confined Spaces:

- Tanks, vessels, and sewers: Confined spaces may contain flammable residues or gases that can form explosive atmospheres.

Transportation and Storage:

- Bulk Storage Tanks: Tanks containing flammable liquids can create explosive atmospheres.

- Fueling Stations: Fuel storage and dispensing areas can pose explosion risks.

- Transport of Hazardous Materials: Transportation vehicles carrying flammable or explosive substances can be at risk.

It’s important to note that in these environments, specific safety measures, hazardous area classification, and equipment with explosion protection are often employed to mitigate the risks associated with explosive atmospheres. Proper hazard assessments and adherence to safety standards and regulations are critical to maintaining safety in such locations.

What are the hazards of explosive atmospheres?

Explosive atmospheres pose significant hazards that can lead to catastrophic incidents, endangering human lives, causing property damage, and harming the environment. The key hazards associated with explosive atmospheres include:

1. Explosion and Fire:

The most immediate and severe hazard is the potential for an explosion or fire, which can result in fatalities, injuries, and extensive damage to equipment and infrastructure.

2. Flying Debris:

Explosions can propel debris and fragments at high velocities, causing injuries and damage to nearby structures and equipment.

3. Overpressure Shockwaves:

Explosions can generate shockwaves with high pressure and velocity, which can damage structures, rupture eardrums, and cause injury to personnel.

4. Toxic Gas Release:

Explosions and fires can release toxic gases, which may pose immediate health risks to those exposed, causing respiratory distress and other health issues.

5. Environmental Impact:

The release of hazardous substances into the environment can lead to soil, air, and water pollution, harming ecosystems and public health.

6. Chain Reactions:

Explosions may trigger secondary explosions, creating a chain reaction and amplifying the hazards.

7. Loss of Life:

Explosive atmospheres can lead to fatalities if people are present in the hazardous area when an incident occurs.

8. Injuries:

Explosions and fires can result in injuries, including burns, trauma, and respiratory issues, which may have long-term consequences.

9. Property Damage:

Explosive incidents can cause extensive damage to structures, equipment, and assets, leading to significant financial losses.

10. Disruption of Operations:

An explosion can disrupt normal business operations, leading to production downtime and financial losses.

11. Economic Consequences:

The aftermath of an explosive atmosphere incident can have wide-ranging economic impacts, including legal liabilities, increased insurance costs, and regulatory fines.

12. Psychological Impact:

Incidents involving explosive atmospheres can have a lasting psychological impact on survivors, witnesses, and first responders.

Preventing and managing the hazards associated with explosive atmospheres requires careful hazard assessments, safety measures, and adherence to regulations and standards specific to the hazardous location. This includes using explosion-proof equipment, controlling ignition sources, and providing safety training to personnel working in such areas. Proper risk mitigation strategies are essential to minimize the potential dangers and protect lives and property.

Preventing Explosive Atmospheres

Reducing the risk of an explosive atmosphere is a multifaceted process that requires a combination of engineering controls, administrative measures, and a strong safety culture. By systematically addressing potential hazards and following best practices, organizations can significantly minimize the risk and enhance workplace safety in environments where explosive atmospheres are a concern.

Reducing the risk of an explosive atmosphere involves a combination of measures and strategies. Here’s an explanation of each of the listed approaches:

1. Quantitative Risk Assessments:

Quantitative risk assessments involve a systematic analysis of the likelihood and consequences of potential explosive atmosphere incidents. This data-driven approach helps identify and prioritize risk-reduction measures.

2. Eliminating or Reducing Combustible Materials:

The most direct way to reduce the risk is to minimize or eliminate the presence of combustible materials (flammable gases, vapors, dust) in the environment through proper storage, handling, and disposal. This can be done by using less flammable materials, substituting non-flammable materials, or reducing the amount of combustible materials present in a given area. For example, a chemical plant might use a less flammable solvent in a manufacturing process, or a paint shop might install a ventilation system to remove flammable vapors.

3. Eliminating or Reducing Ignition Sources:

Identify and eliminate or control potential ignition sources, such as electrical equipment, hot surfaces, open flames, and sparks. This can be done by using non-sparking tools and equipment, grounding electrical equipment, and avoiding open flames and hot surfaces. For example, an oil refinery might use non-sparking tools when working on pipelines, or a grain silo might install explosion-proof lighting.

Need to identify and control potential ignition sources, including electrical equipment, open flames, sparks, and hot surfaces. Implement appropriate safety measures, such as grounding and bonding, to prevent electrostatic discharges.

4. Controlling Oxygen Levels:

This can be done by purging an area with an inert gas or by using a ventilation system to remove flammable gases and vapors. For example, a mine might use an inert gas to purge the atmosphere before entering a confined space, or a fuel storage tank might be equipped with a nitrogen blanketing system.

5. Providing Adequate Ventilation:

Proper ventilation systems can disperse flammable gases or dust, preventing their accumulation. This helps to dilute flammable gases and vapors and prevent them from reaching explosive concentrations. For example, a woodworking shop might install a ventilation system to remove sawdust and other flammable dust particles, or a chemical plant might use a ventilation system to remove hazardous fumes. Ventilation also maintains safe oxygen levels in confined spaces.

6. Intrinsic Safety:

Intrinsic safety is a design approach that aims to reduce the risk of explosions by preventing the formation of explosive atmospheres in the first place. This type of design safety ensures it cannot produce an arc, spark, or heat that could ignite flammable gases or dust. This technology minimizes the risk of ignition. This can be done by using low-energy circuits and components, or by designing equipment in a way that prevents the release of flammable substances. For example, an intrinsically safe phone might be used in a hazardous environment where there is a risk of explosion.

7. Explosion-Proof Equipment:

Explosion-proof equipment is designed to contain any explosion that may occur within it, preventing it from igniting the surrounding atmosphere. This is particularly crucial for electrical and mechanical equipment. This type of equipment is often used in hazardous environments where there is a risk of explosion, such as oil refineries and chemical plants.

8. Hazardous Zoning:

Classify and zone hazardous areas using systems like ATEX (Zone classification) or NEC (Division classification) to designate where explosive atmospheres are likely to exist. This guides the selection of appropriate equipment and safety measures. Hazardous zoning is the process of dividing a workplace into different zones based on the level of risk of an explosion. This information is then used to select the appropriate equipment and procedures for each zone. For example, a zone where there is a high risk of the explosion might require the use of intrinsically safe equipment and explosion-proof lighting.

9. Housekeeping:

Regular housekeeping practices, such as cleaning and removing dust or residues, help prevent the buildup of combustible materials that could lead to explosive atmospheres.

10. Specialized Safety Training:

Ensure that personnel working in or around hazardous areas receive specialized safety training, covering hazard awareness, safe work practices, and emergency response procedures.

11. Personal Protective Equipment (PPE):

Provide suitable PPE, such as flame-resistant clothing, goggles, and respiratory protection, to employees working in areas with potentially explosive atmospheres to mitigate the impact of incidents.

12. Safe handling and storage: Combustible materials should be handled and stored in a safe manner to minimize the risk of spills and leaks. This includes using proper containers and labeling, and storing materials in a cool, dry place away from ignition sources. Use suitable containers, tanks, and storage systems to minimize the risk of leakage or dispersion.

13. Safety procedures: Safety procedures should be developed and implemented to address all potential hazards, including the risk of explosive atmospheres. These procedures should cover topics such as hazard identification, risk assessment, and risk mitigation measures. Develop and enforce safety procedures, including entry permits, work permits, and isolation procedures for hazardous areas.

14. Emergency response plans: Emergency response plans should be developed including evacuation, medial emergency or fire and implemented to address the potential consequences of an explosion, such as fire, injury, and property damage. These plans should include steps to evacuate personnel, extinguish fires, and provide first aid. Conduct regular emergency drills to ensure that personnel are prepared to respond effectively.

15. Compliance with regulations: Employers must comply with all applicable regulations related to explosive atmospheres. These regulations may vary depending on the jurisdiction, but they typically cover topics such as equipment selection, employee training, and emergency preparedness.

16. Monitoring and testing: Equipment and systems used to reduce the risk of explosives atmospheres should be monitored and tested regularly to ensure that they are functioning properly. This includes testing ventilation systems, fire and explosion detection and suppression systems, and hazardous area classification systems.

Implement gas detection systems to continuously monitor gas concentrations in hazardous areas. Regularly test and calibrate safety systems and equipment to ensure their effectiveness.

17. Preventive maintenance: Preventive maintenance should be performed on all equipment and systems used to reduce the risk of explosive atmospheres. This helps to identify and address potential problems before they cause an explosion. Schedule and perform preventive maintenance on equipment and systems to detect and rectify potential issues before they become hazards.

18. Continuous improvement: Employers should continuously review and improve their programs for reducing the risk of explosive atmospheres. This includes identifying new hazards, developing new risk mitigation measures, and evaluating the effectiveness of existing programs. Regularly review safety procedures, incident reports, and near misses to identify areas for improvement and implement necessary changes.

By implementing these measures and strategies, organizations can significantly reduce the risk of an explosive atmosphere and promote a safer work environment. Proper hazard assessment, risk mitigation, and compliance with relevant regulations and standards are essential to achieve this goal. The specific measures that are appropriate will vary depending on the specific workplace and the hazards present.

Case Studies

Case Study: Beirut Port Explosion

One of the recent case studies of an explosion in industry is the Beirut Port blast that occurred on August 4, 2020. The explosion was caused by the accidental ignition of 2,750 tonnes of ammonium nitrate, a highly explosive chemical, that was stored in a warehouse for six years without proper safety measures. The blast resulted in more than 200 deaths, 6,500 injuries, and widespread damage to buildings and infrastructure in the surrounding area. The explosion also released toxic gases and dust into the air, posing health and environmental risks for the population. The incident highlighted the need for better regulation, inspection, and management of hazardous materials in ports and other industrial facilities.

Another example of an explosion in industry is the dust explosion that occurred in a zirconium powder plant in China on December 9, 2010. The explosion was triggered by a spark in a non-operational mixer that contained zirconium dust. The flame and pressure from the initial explosion caused secondary explosions of dust that had accumulated in the plant. The explosions killed three workers and injured several others. The plant was severely damaged and had to be shut down for several months. The investigation revealed that the plant had poor ventilation, inadequate dust collection systems, and insufficient training and supervision of workers .

These incidents illustrate some of the common causes and effects of explosions in industry, such as:

- Improper storage, handling, or disposal of flammable or explosive substances

- Ignition sources such as sparks, flames, static electricity, or friction

- Accumulation of combustible dust or vapors in confined spaces

- Lack of adequate safety measures, such as ventilation, fire suppression, explosion relief, or personal protective equipment

- Human errors, negligence, or violations of safety rules or regulations

To prevent or mitigate such incidents, some of the lessons learned from past accidents are:

- Conduct regular risk assessments and audits of industrial facilities and processes

- Implement and enforce strict safety standards and procedures for dealing with hazardous materials

- Install and maintain appropriate equipment and systems to prevent or control ignition sources, dust accumulation, and gas leaks

- Provide adequate training and education for workers and managers on the hazards and precautions of working with explosive substances

- Develop and practice emergency response plans and drills for dealing with potential explosions or fires

Case Study: West Fertilizer Company Explosion

On April 17, 2013, an explosion occurred at the West Fertilizer Company plant in West, Texas, killing 15 people and injuring over 200. The explosion was caused by a fire in a warehouse containing ammonium nitrate, a fertilizer that is also used in explosives. The fire ignited the ammonium nitrate, causing a massive explosion that destroyed the warehouse and damaged surrounding buildings.

The investigation into the explosion found that the West Fertilizer Company had failed to comply with a number of safety regulations, including regulations related to the storage of ammonium nitrate. The company had also failed to implement adequate safety procedures and to train employees on the hazards of ammonium nitrate.

Lessons Learned

The West Fertilizer Company explosion is a reminder of the importance of safety in industrial settings. Employers must comply with all applicable safety regulations and implement adequate safety procedures to protect their employees and the public. Employers must also train employees on the hazards of the materials they are working with and how to work safely.

Notable Incidents Related to Explosive Atmospheres

Here are some other notable incidents related to explosive atmospheres:

- Piper Alpha oil platform explosion (1988): An explosion on the Piper Alpha oil platform in the North Sea killed 167 people, making it the deadliest offshore oil disaster in history. The explosion was caused by a gas leak that ignited and caused a series of explosions.

- Phillips 66 refinery explosion (1989): An explosion at the Phillips 66 refinery in Borger, Texas, killed 23 people and injured 314. The explosion was caused by a leak of highly flammable propane gas that ignited.

- Buncefield oil depot explosion (2005): An explosion at the Buncefield oil depot in Hertfordshire, England, caused an estimated £750 million in damage. The explosion was caused by a leak of gasoline that ignited and caused a series of explosions.

These incidents are a reminder of the serious hazards posed by explosive atmospheres. Employers and workers must take all necessary precautions to prevent explosions and to protect themselves and others from the consequences of an explosion.

How to Reduce the Risk of an Explosion

There are a number of things that can be done to reduce the risk of an explosion, including:

- Eliminating or reducing combustible materials

- Eliminating or reducing ignition sources

- Controlling oxygen levels

- Providing adequate ventilation

- Implementing safe work practices

- Training employees on the hazards of explosive atmospheres

- Complying with all applicable safety regulations

By taking these steps, employers and workers can help to create a safer workplace for everyone.

Regulations and Standards

Regulations and standards play a critical role in ensuring the safety of workers and the public in environments where explosive atmospheres may exist. Here’s an overview of the regulatory bodies, authorities, and safety standards relevant to managing these risks:

OSHA (Occupational Safety and Health Administration)

OSHA is a division of the United States Department of Labor that is responsible for ensuring safe and healthy working conditions for employees by setting and enforcing standards and by providing training, outreach, and education.

- OSHA is the primary federal agency in the United States responsible for ensuring workplace safety and health.

- OSHA sets and enforces safety regulations, conducts inspections, and provides guidance on safety practices.

- OSHA’s General Industry Standard, particularly 29 CFR 1910 Subpart S, contains regulations related to electrical equipment in hazardous locations.

- 29 CFR 1910.1030, which covers the use of flammable and combustible liquids

- 29 CFR 1910.1047, which covers the use of combustible dust

NFPA (National Fire Protection Association):

The NFPA is a non-profit organization that develops and publishes consensus standards and recommended practices intended to minimize the possibility and effects of fire and other hazards.

- NFPA is a prominent organization that develops and publishes codes and standards related to fire safety and protection.

- NFPA 70, also known as the National Electrical Code (NEC), provides comprehensive guidelines for electrical installations, particularly in hazardous areas.

- NFPA 68, Standard on Explosion Protection by Deflagration Venting.

- NFPA 497 and NFPA 499 offer guidance on the classification and protection of combustible dusts.

Safety Standards and Guidelines:

Compliance with safety standards and regulations is essential for preventing explosions and protecting workers from the consequences of an explosion. Safety standards and regulations are based on the best available knowledge and experience, and they are designed to minimize the risk of explosions. By complying with safety standards and regulations, employers and workers can help to create a safer workplace for everyone.

1. Importance of Compliance:

- Compliance with safety standards and regulations is crucial to minimize the risk of explosive atmospheres and ensure the safety of workers and the public.

- Compliance helps organizations identify and address potential hazards, select appropriate equipment, and establish safety protocols.

2. Key Standards and Regulations:

a. NFPA 70 (National Electrical Code – NEC):

- NEC provides detailed requirements for electrical installations in hazardous locations.

- It covers wiring methods, equipment, classification of hazardous areas, and the selection of explosion-proof equipment.

b. NFPA 497 (Recommended Practice for the Classification of Flammable Liquids, Gases, or Vapors and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas):

- NFPA 497 provides guidelines for classifying and designating hazardous areas based on the properties of flammable substances.

- It outlines safety measures for electrical installations in chemical process areas.

c. NFPA 499 (Recommended Practice for the Classification of Combustible Dusts and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas):

- NFPA 499 addresses the classification of combustible dusts and safety measures for electrical installations in areas where such dusts are present.

d. ATEX Directive (94/9/EC – Atmosphères Explosibles Directive):

- ATEX is a European directive that sets the standards for equipment and safety systems used in potentially explosive atmospheres.

- It defines equipment categories, hazard assessment, and conformity requirements.

e. IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres):

- IECEx is an international system for certification to standards related to equipment for use in explosive atmospheres.

- It provides a globally recognized framework for ensuring the safety of electrical and non-electrical equipment.

f. IEC 60079 Series (International Electrotechnical Commission Standards for Explosive Atmospheres):

- The IEC 60079 series comprises standards that specify the requirements for electrical and non-electrical equipment used in hazardous areas.

Compliance with these standards and regulations is vital to mitigating the risks associated with explosive atmospheres and ensuring the safety of personnel and facilities in industries where such hazards are present. Organizations should remain informed about updates and changes to these standards to maintain a safe working environment.

Conclusion

In this article, we have discussed the main concepts and principles of explosive atmospheres, their causes and effects, and the methods and standards for risk assessment and prevention. We have also reviewed some of the current challenges and opportunities in explosive atmosphere management, such as new technologies, regulations, and best practices.

Explosive atmospheres pose a serious threat to the safety and health of workers, facilities, and the environment, and therefore require a comprehensive and systematic approach to understand and prevent them. By applying the knowledge and skills learned in this outline, we can contribute to the improvement of explosive atmosphere management and reduce the potential for accidents and incidents. Furthermore, we can anticipate and adapt to the future trends and advancements in this field, such as digitalization, automation, and innovation, and enhance our competitiveness and performance.

- Future advancements in explosive atmosphere management are likely to focus on advanced detection and prevention technologies, such as improved gas detection systems and smart sensors.

- The integration of automation, real-time monitoring, and data analytics will enhance safety and enable more proactive risk management.

- Sustainable and eco-friendly solutions for minimizing environmental impacts of explosions will gain importance.

In a rapidly evolving industrial landscape, it is crucial for organizations to stay up-to-date with safety standards, embrace cutting-edge technologies, and cultivate a culture of safety to effectively manage the risks associated with explosive atmospheres. Ultimately, by understanding and preventing these hazards, we can promote safety, protect lives, and safeguard the environment for the well-being of all.

FAQs

What are the warning signs of an explosive atmosphere?

An explosive atmosphere is a mixture of flammable substances (such as gases, vapors, mists or dusts) and air that can ignite and cause an explosion. Some warning signs of an explosive atmosphere are:

- A strong or unusual smell of gas or other flammable substances.

- A hissing or roaring sound of escaping gas or pressure.

- A visible cloud, mist or dust of flammable substances.

- Sparks, flames or hot surfaces near flammable substances.

- Damaged or leaking pipes, valves, tanks or containers that hold flammable substances.

- Visible dust or mist in the air

How can you protect yourself in an explosive atmosphere?

You can protect yourself in an explosive atmosphere by following these safety measures:

- Avoid creating sources of ignition, such as open flames, sparks, static electricity, friction or heat.

- Use explosion-proof equipment and tools that are designed to prevent ignition in explosive atmospheres.

- Wear appropriate personal protective equipment (PPE), such as flame-resistant clothing, gloves, goggles and helmets.

- Follow the instructions and procedures for working in explosive atmospheres, such as checking the gas concentration, ventilation and emergency plans.

- Report any signs of an explosive atmosphere to your supervisor or manager and evacuate the area if necessary.

What should you do if you suspect an explosive atmosphere?

If you suspect an explosive atmosphere, you should do the following:

- Stop your work and turn off any sources of ignition.

- Alert your co-workers and supervisor or manager about the situation.

- Evacuate the area and move to a safe distance.

- Call the emergency services and inform them about the location and nature of the potential explosion.

- Do not re-enter the area until it is declared safe by the authorities.

- Do not attempt to investigate the source of the hazard or to operate any equipment.

What should you do if an explosion occurs?

If an explosion occurs, you should immediately evacuate the area and call 911. If you are injured, seek medical attention immediately. Here are some additional tips for staying safe in explosive atmospheres:

- Protect yourself from flying debris, fire and smoke by taking cover under a sturdy table or behind a solid wall

- Stay calm and follow the instructions of the emergency services or your supervisor or manager

- Never smoke or use open flames in an explosive atmosphere.

- Do not operate any electrical equipment that is not specifically designed for use in explosive atmospheres.

- Be aware of the potential for static electricity buildup and take steps to prevent it, such as grounding yourself and avoiding synthetic clothing.

- Move away from the explosion site and avoid any secondary explosions or hazards

- Report any spills or leaks immediately. Report to the designated assembly point and wait for further instructions

References

1. https://www.hsimagazine.com/article/explosive-atmospheres/

Your one click can make a difference

Keep sharing and promoting health and safety awareness!

Related posts:

20 Best Ways to Improve Safety Performance in the Workplace

Discover the 20 best ways to improve safety performance at workplace, including actionable strategies for hazard prevention, employee engagement, safety training, and fostering a culture of well-being.

Strategies for Using Social Media to Promote Public Safety Awareness

Discover how social media can be used to enhance public safety awareness. Learn effective strategies to share vital information, engage communities, and build trust during emergencies.

Brighten Up Your Diwali, Not the Emergency Room: Diwali Safety Tips

Diwali is a time for joy and celebration. But with fireworks, candles, and electrical decorations, accidents can happen. Learn essential Diwali safety tips to Protect yourself, your loved ones and others from fire hazards, electrical shocks, and other risks.

We are a group of volunteers and starting a new scheme in our community.

Your web site provided us with valuable info to work on. You’ve done an impressive job and our whole community will be thankful to

you.

Hello, I enjoy reading all of your article post.

I wanted to write a little comment to support you. Silvoria

Thanks for ones marvelous posting! I actually enjoyed reading it, you

could be a great author.I will make certain to bookmark your blog and may come back sometime soon. I

want to encourage continue your great job, have a nice morning!

Zabawka

You are welcome, and we are happy to know you liked the content!

Hey There. I discovered your blog using msn. That is a really neatly

written article. I’ll be sure to bookmark it

and come back to read extra of your useful information. Thank you for the post.

I will definitely return.